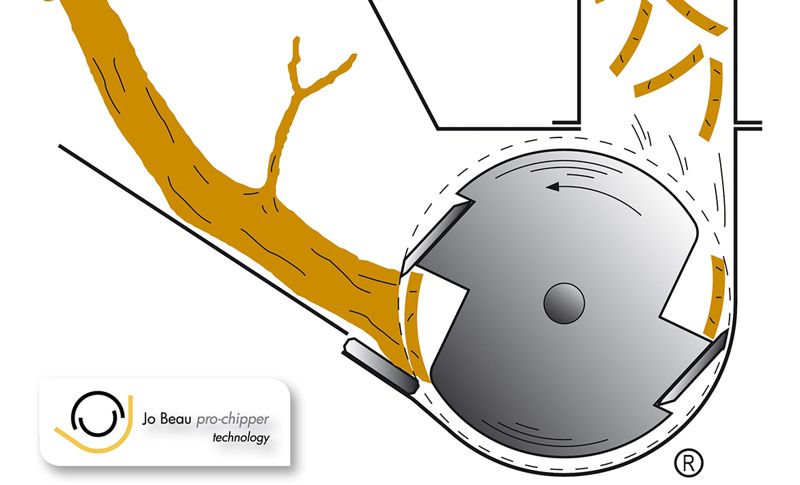

How does the Jo Beau ® drum technology™ work?

What are the functions performed by the Jo Beau drum technology?

- Chipping

- Pulling in the branches

- Ejecting the wood chips

The principle of Jo Beau drum technology includes the following elements:

- The heavy steel knife drum

- Two industrial-quality roller bearings

- One set of knives (2 pcs)

- And a counter blade

When the blade drum is set in motion, the blades pass the counter blade at a smaller distance of half a millimetre. Almost like scissors so finely tuned. With the motor set to high speed, you boost the rotational speed of the drum to 2400 rpm. Now you are ready to feed the branches into the machine.

As the razor-sharp edge of the blades, made of the highest quality steel, slides into the freshly cut wood, the design is such that the branch is pulled in during the same movement without the machine operator having to make any effort at all. The high speed of the blade drum therefore provides an unseen working speed at which the branch is pulled in. Both the main branch, side branches, twigs and foliage are chopped into small uniform pieces between the blades and the counter blade.

The advantage of the Jo Beau drum technology is that wood species such as pollard willow with a long fibrous structure are shredded very smoothly into chips without the long fibres remaining spinning anywhere in the machine.

The question also sometimes comes whether other woody species like bamboo or other lighter crops like corn stalks are processed just as well. Here too, the answer is positive! If the material to be processed has enough 'volume', Jo Beau technology is the right chipping principle for your job.

Very light grasses also qualify, as long as you add a branch (volume) during chipping.

We would be happy to explain more during a no-obligation demonstration at your premises. Contact us here.